355nm UV Laser Marking For Logo, Button Label On Plastic

In today's dynamic marketplace, businesses are constantly seeking innovative ways to distinguish their products from the competition. One area where this elevation in artistic expression has taken center stage is the field of UV laser marking for logo and button label engraving on plastic.

Consulting products

- Product Description

- Parameter

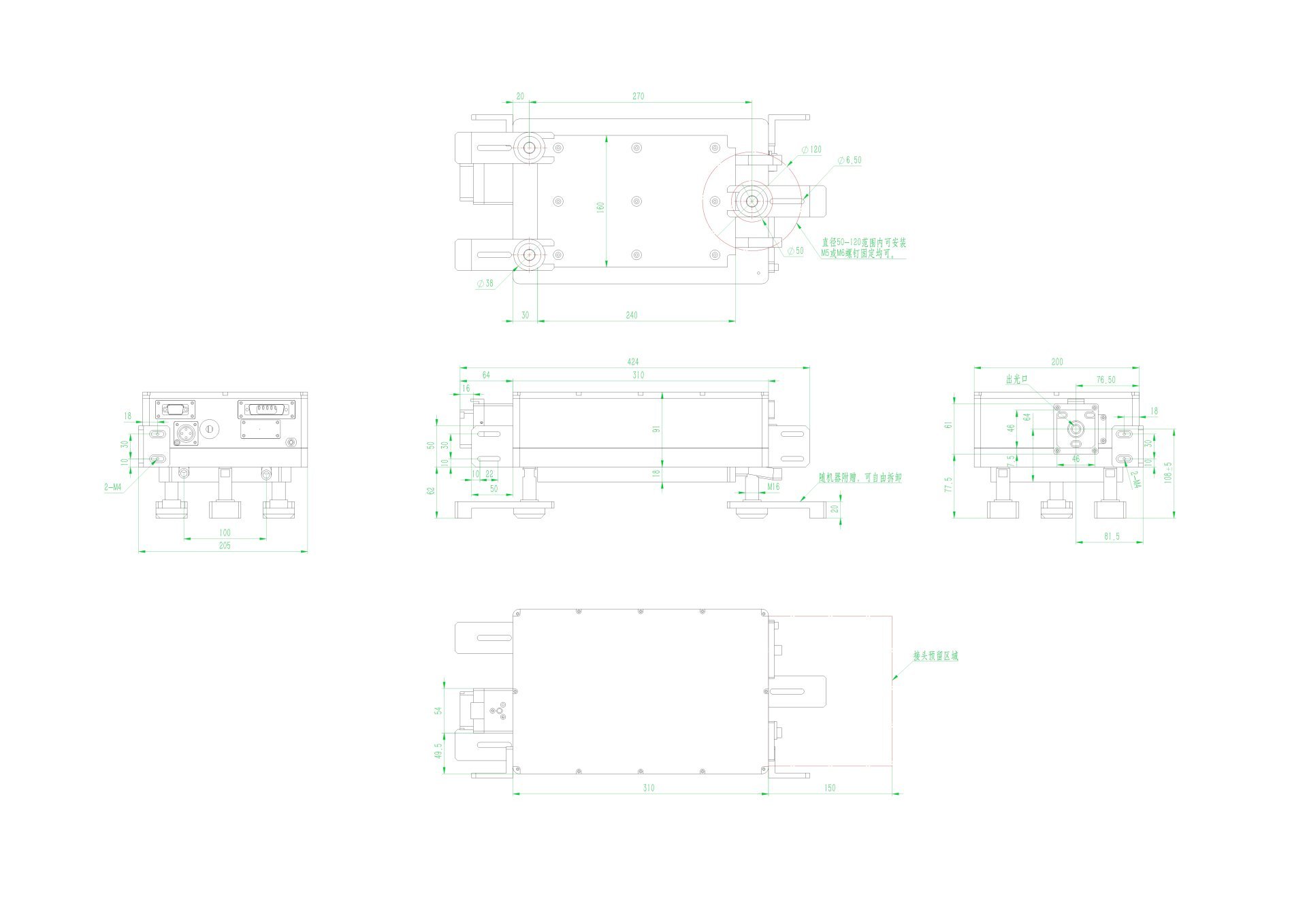

- Dimensional Drawing

- Application Field

-

- Commodity name: 355nm UV Laser Marking For Logo, Button Label On Plastic

- Commodity ID: 1041772479862628

In today's dynamic marketplace, businesses are constantly seeking innovative ways to distinguish their products from the competition. One area where this elevation in artistic expression has taken center stage is the field of UV laser marking for logo and button label engraving on plastic.

355nm UV Laser Marking for Logo, Button Label on Plastic

UV Laser Marking: Elevating Logo and Button Label Artistry on Plastic Surfaces

In today's dynamic marketplace, businesses are constantly seeking innovative ways to distinguish their products from the competition. One area where this elevation in artistic expression has taken center stage is the field of UV laser marking for logo and button label engraving on plastic.

Gone are the days when traditional labeling methods relied on mundane processes. Now, with the advent of cutting-edge UV laser technology, businesses can breathe life into their branding efforts, imbuing their products with an aura of sophistication and finesse.

UV laser marking, harnessing the power of ultraviolet light, offers a more refined and precise alternative to conventional marking techniques. Its exceptional versatility enables manufacturers to imprint intricate corporate logos, captivating designs, and informative button labels onto various plastic surfaces. Whether it is the sleek facade of a high-end electronic device or the lustrous body of an elegant cosmetic container, UV laser marking ensures a seamless integration of aesthetics and functionality.

This process involves using high-power UV lasers to create a controlled interaction between the laser beam and the plastic substrate. By carefully adjusting the laser intensity, duration, and focus, manufacturers can achieve remarkable results. The laser selectively alters the molecular structure of the plastic, causing a subtle and permanent color change, resulting in an elegant and eye-catching label or logo.

The advantages of UV laser marking in comparison to traditional methods are manifold. Firstly, it guarantees superior durability and longevity. The markings won't fade, crack, or peel off over time, ensuring that the product maintains its visual appeal throughout its lifespan. Secondly, UV laser marking offers impeccable precision, enabling manufacturers to achieve intricate details, sharp lines, and exquisite finishes. This level of flawless craftsmanship enhances brand perception and bolsters customer trust in the product's quality and attention to detail.

Moreover, UV laser marking is an environmentally friendly solution as it eliminates the need for inks, solvents, and other potentially harmful additives. This not only reduces waste but also contributes to a greener manufacturing process, aligning with the ever-growing demand for sustainable practices.

In conclusion, the advent of UV laser marking technology has revolutionized the way logo and button labels are imprinted on plastic surfaces. This cutting-edge technique provides businesses with an exceptional opportunity to elevate their products from mere commodities to symbols of artistic excellence. With its enduring durability, precise execution, and eco-friendliness, UV laser marking ensures that brand aesthetics and functionality coexist harmoniously, captivating consumers and leaving a lasting impression.

RFH F9 series Water cooled UV laser's power range is 3w-5w .Comparing with its kinds, F9 series UV laser features with rugged sealed cavity, extremely compact size, simple and robust, high stability, high efficiency, high reliability and excellent laser beam quality.Its compact design suggests no necessity in building big light path, which greatly reduces space and cost and makes it easy to be installed into UV laser marking machines. In addition, F9 series cavity structure has more stability and more excellent scalability, which means the same laser cavity can produce multi-power lasers , and the stability of different power ranges is greatly improved.

Key words:- 355nm UV Laser

- Marking for Logo

- Button Label on Plastic

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体