355nm Uv Laser Cold Marking Plastic Logo

In the world of branding and personalization, creating a lasting impression on plastic surfaces can be a challenging endeavor. Traditional methods often fall short when it comes to achieving optimal precision and durability. However, with the emergence of 355nm UV laser technology, the landscape of plastic logo marking has been forever transformed. This cutting-edge solution promises impeccable results, combining cold marking capabilities with unmatched efficiency.

Consulting products

- Product Description

- Parameter

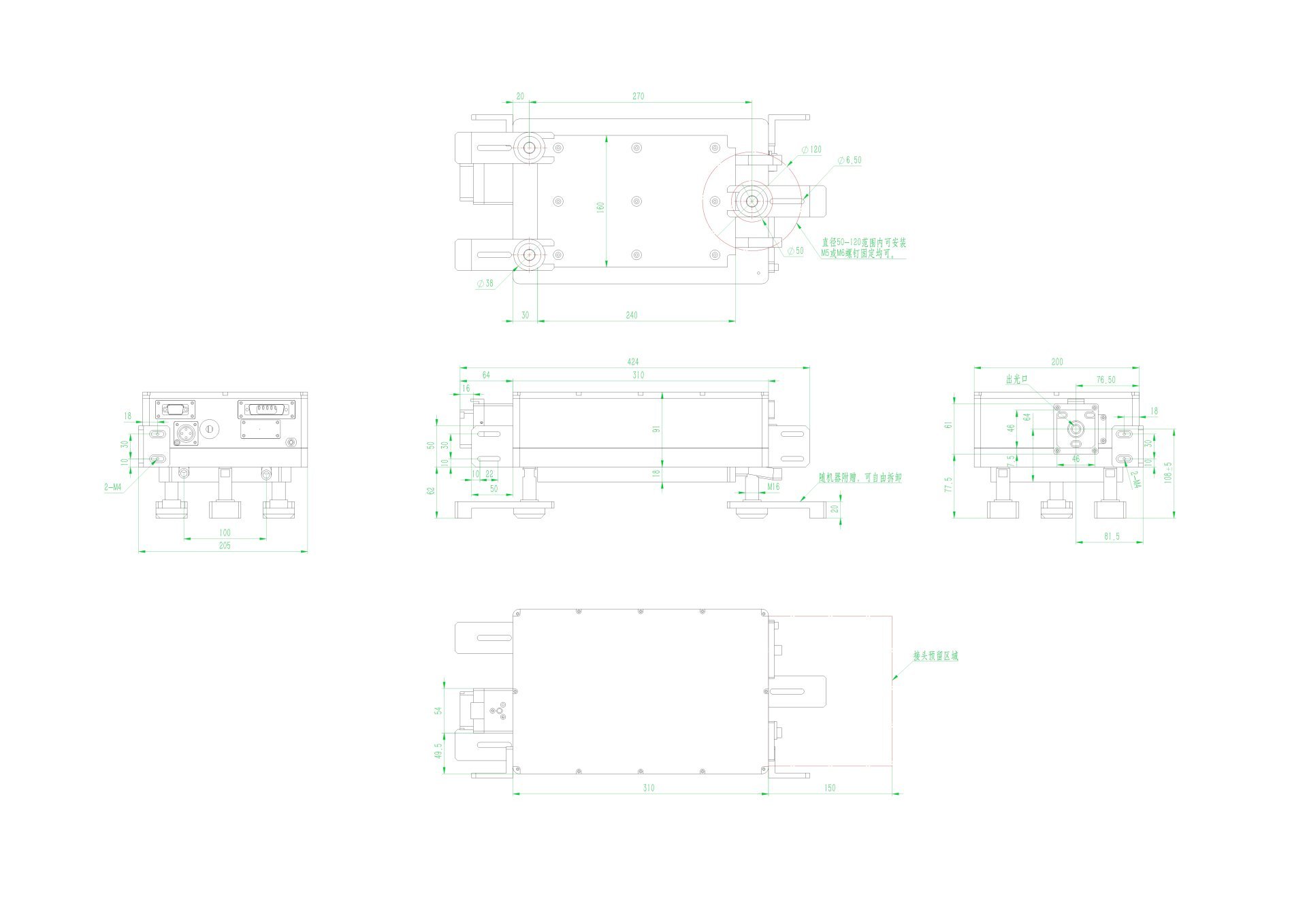

- Dimensional Drawing

- Application Field

-

- Commodity name: 355nm Uv Laser Cold Marking Plastic Logo

- Commodity ID: 10417724798626283

In the world of branding and personalization, creating a lasting impression on plastic surfaces can be a challenging endeavor. Traditional methods often fall short when it comes to achieving optimal precision and durability. However, with the emergence of 355nm UV laser technology, the landscape of plastic logo marking has been forever transformed. This cutting-edge solution promises impeccable results, combining cold marking capabilities with unmatched efficiency.

355nm uv laser cold marking plastic logo

355nm UV Laser: The Ultimate Solution for Cold Marking Plastic Logos

In the world of branding and personalization, creating a lasting impression on plastic surfaces can be a challenging endeavor. Traditional methods often fall short when it comes to achieving optimal precision and durability. However, with the emergence of 355nm UV laser technology, the landscape of plastic logo marking has been forever transformed. This cutting-edge solution promises impeccable results, combining cold marking capabilities with unmatched efficiency.

The 355nm UV laser is an ingenious tool that harnesses the power of ultraviolet light to create permanent marks on plastic surfaces. Unlike conventional methods that rely on heat or chemicals, this advanced technology operates through a cold marking process, minimizing the risk of damage or distortion to the plastic material. This not only ensures the longevity and structural integrity of the item but also allows for fine details and intricate designs to be flawlessly embossed.

Precision is the cornerstone of any successful branding endeavor, and the 355nm UV laser excels in this regard. With its focused beam size, this laser can achieve high-resolution markings, resulting in crisp lines and sharp edges that enhance the overall aesthetic appeal of the logo. Whether it's a small emblem or a complex design, the 355nm UV laser effortlessly brings it to life, capturing the essence of the brand in every detail.

Furthermore, the cold marking process of the 355nm UV laser offers remarkable versatility when it comes to plastic logo customization. This technology can be applied to a wide range of plastic materials, including acrylic, ABS, polycarbonate, and more. Whether it's for promotional items, packaging, or product labeling, the 355nm UV laser guarantees consistent and visually stunning results across various plastic substrates.

Durability is another key aspect that sets the 355nm UV laser apart from other marking methods. The marks made by this laser are highly resistant to fading, peeling, or rubbing off, ensuring that the logo remains vibrant and legible over time. This is particularly crucial for products that are exposed to harsh environmental conditions or frequent handling, as it ensures the longevity and brand integrity of the item.

In addition to its marking capabilities, the 355nm UV laser offers an environmentally friendly solution for plastic logo customization. With no need for chemicals, solvents, or excessive energy consumption, this technology minimizes its ecological footprint, making it a sustainable choice for businesses concerned about their environmental impact. By opting for the 355nm UV laser, companies can showcase their commitment to both quality branding and eco-conscious practices.

Embracing the power of the 355nm UV laser for cold marking plastic logos opens up limitless creative possibilities. Businesses can now confidently showcase their brand identity on a variety of plastic products, from electronic devices to automotive components, leaving an indelible mark that speaks volumes about their commitment to excellence. This innovative technology ensures not only precision and durability but also elevates the overall branding experience for both businesses and consumers.

In conclusion, the 355nm UV laser has revolutionized the world of plastic logo marking, offering an unparalleled combination of precision, longevity, and sustainability. Whether it's for corporate branding, promotional items, or retail packaging, this advanced technology provides a solution that is as efficient as it is visually captivating. So, embrace the power of the 355nm UV laser and witness your plastic logos come to life with extraordinary brilliance and finesse.

To meet the market demand, RFH newly developed S9 series UV laser . Comparing with its kinds, S9 series UV laser features with rugged sealed cavity, extremely compact size, simple and robust, high stability, high efficiency, high reliability and excellent laser beam quality.Its compact design suggests no necessity in building big light path, which greatly reduces space and cost and makes it easy to be installed into UV laser marking machines. In addition, S9 series cavity structure is more stability and more excellent scalability, which means the same laser cavity can be produces multi-power lasers , and the stability of different power ranges is greatly improved.

RFH F9 series Water cooled UV laser's power range is 3w-5w .Comparing with its kinds, F9 series UV laser features with rugged sealed cavity, extremely compact size, simple and robust, high stability, high efficiency, high reliability and excellent laser beam quality.Its compact design suggests no necessity in building big light path, which greatly reduces space and cost and makes it easy to be installed into UV laser marking machines. In addition, F9 series cavity structure has more stability and more excellent scalability, which means the same laser cavity can produce multi-power lasers , and the stability of different power ranges is greatly improved.

Key words:- 355nm uv laser

- cold marking plastic logo

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体