Laser Cutting, Engraving & Marking ABS Plastic

In the fascinating realm of laser technology, where innovation knows no bounds, one material stands out for its versatility and usefulness - ABS plastic. Acrylonitrile Butadiene Styrene (ABS) has become a staple in various industries, owing to its durability, lightweight nature, and remarkable adaptability. This remarkable thermoplastic polymer has piqued the interest of laser cutting, engraving, and marking enthusiasts, unlocking a world of endless possibilities.

Consulting products

- Product Description

- Parameter

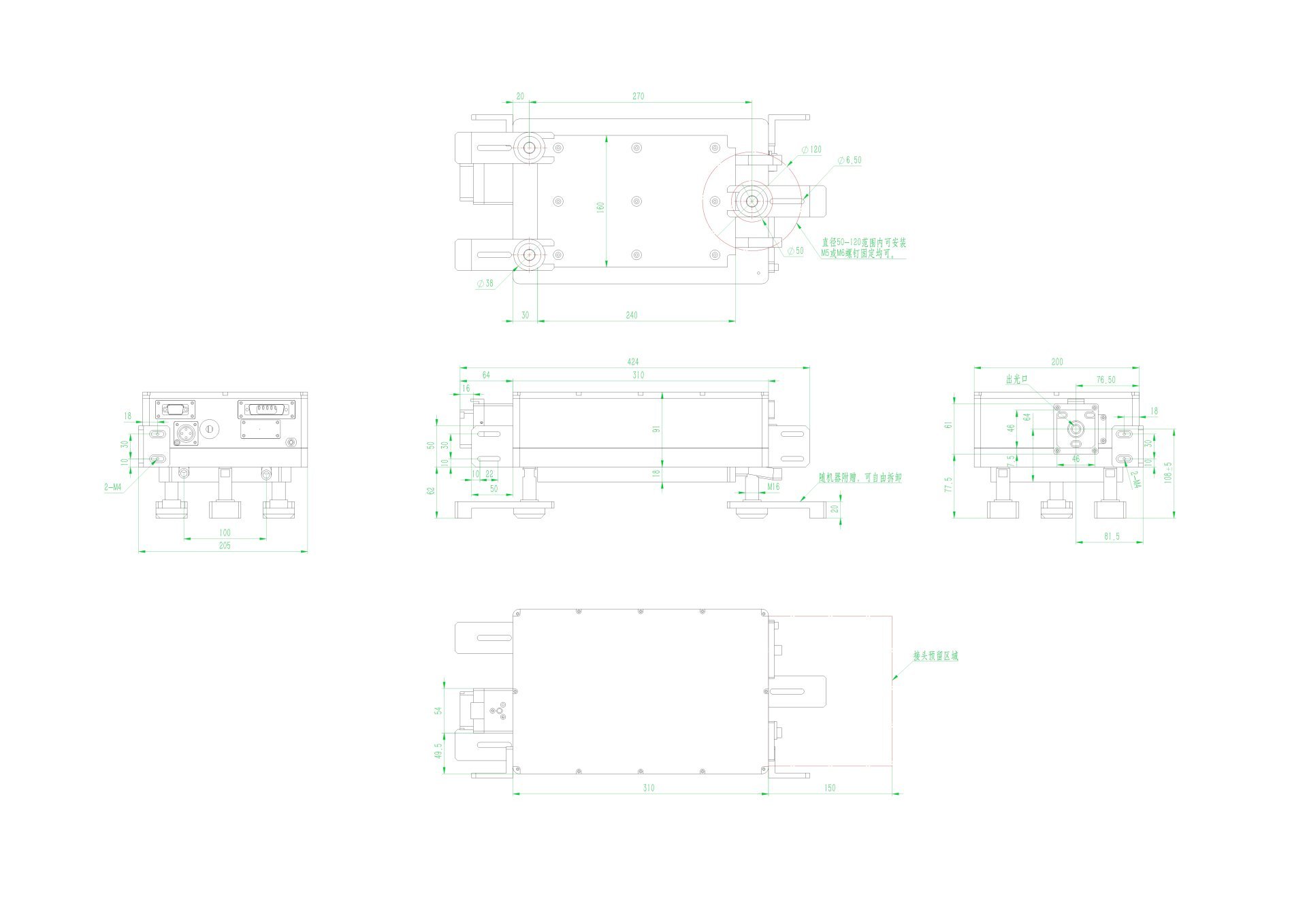

- Dimensional Drawing

- Application Field

-

- Commodity name: Laser Cutting, Engraving & Marking ABS Plastic

- Commodity ID: 1041772479862628352-4

In the fascinating realm of laser technology, where innovation knows no bounds, one material stands out for its versatility and usefulness - ABS plastic. Acrylonitrile Butadiene Styrene (ABS) has become a staple in various industries, owing to its durability, lightweight nature, and remarkable adaptability. This remarkable thermoplastic polymer has piqued the interest of laser cutting, engraving, and marking enthusiasts, unlocking a world of endless possibilities.

Laser Cutting, Engraving & Marking ABS Plastic

Illuminating the Boundaries: Laser Cutting, Engraving & Marking ABS Plastic

In the fascinating realm of laser technology, where innovation knows no bounds, one material stands out for its versatility and usefulness - ABS plastic. Acrylonitrile Butadiene Styrene (ABS) has become a staple in various industries, owing to its durability, lightweight nature, and remarkable adaptability. This remarkable thermoplastic polymer has piqued the interest of laser cutting, engraving, and marking enthusiasts, unlocking a world of endless possibilities.

Laser cutting ABS plastic offers a precision and finesse that traditional cutting methods simply cannot match. With a gentle yet powerful touch, the laser effortlessly carves intricate designs and precise shapes into the material, transforming it into a work of art. Gone are the days of cumbersome saws and heat-inducing tools; laser cutting allows for clean cuts and smooth edges, ensuring a seamless result that exudes professionalism and refinement.

But it doesn't end there. Laser engraving on ABS plastic adds a layer of personalization and creativity that ignites the imagination. Whether it's a logo, artwork, or intricate patterns, the laser intricately etches these designs onto the surface, creating a lasting impression. The ability to engrave ABS plastic offers a wide range of applications, from decorative pieces to functional components, elevating the material to new heights of sophistication.

Furthermore, laser marking ABS plastic has become a favored method for branding and identification. With impeccable precision, the laser interacts with the material's surface, leaving behind a permanent mark that defies wear and tear. This makes it ideal for adding logos, serial numbers, barcodes, or any other custom markings needed for product identification. The durability of the laser-marked ABS plastic ensures the message lasts, maintaining a professional appearance throughout its lifespan.

The advantages of laser cutting, engraving, and marking ABS plastic go beyond aesthetics. The laser's non-contact nature and focused heat minimize the risk of damaging the material, preserving its structural integrity. This level of precision not only guarantees a high-quality finished product but also reduces waste, making it a sustainable and environmentally friendly choice. The ability to work with ABS plastic opens doors to manufacturers seeking efficiency and eco-conscious solutions.

In the ever-evolving landscape of design and manufacturing, ABS plastic continues to showcase its versatility and adaptability. From automotive parts and consumer electronics to signage and artistic creations, its presence is felt in countless industries. With laser cutting, engraving, and marking, ABS plastic becomes a medium of choice for those seeking to push boundaries and unleash their artistic vision.

The possibilities are endless when laser technology and ABS plastic collaborate. As laser enthusiasts explore the potential of this remarkable material, remarkable creations arise. Imagination finds freedom in intricate laser-cut sculptures, personalized engraved gifts, and precisely marked components that exude professionalism. The seamless blend of technology and creativity creates an undeniable allure that captivates both creators and admirers alike.

In conclusion, the marriage of laser cutting, engraving, and marking with ABS plastic shines a spotlight on a groundbreaking union. It enables the creation of precise and refined designs, personalization possibilities, and durable branding solutions. The versatile nature of ABS plastic, combined with the unrivaled precision of lasers, opens doors to a whole new world of artistic expression and manufacturing efficiency. Embrace the bond between laser technology and ABS plastic, and unlock the infinite potential that awaits.

S9-Y series solid state pulsed UV laser is ultra compact. The whole part of power supply is integrated into the laser head. This makes the size of the laser more smaller, and the integration into a system more easier and convenient. S9-Y series is of short pulse width(<12ns@30k),superior beam quality(M²<1.2) and perfect laser sport quality(beam circularity>90%).

Key words:- Laser Cutting

- Engraving & Marking

- Marking ABS Plastic

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体