Laser Marking On Plastics Used In Industry Such As ABS, PP, PVC, PP, PET, PC, Nylon

In the realm of industrial plastics, where durability meets functionality, a groundbreaking technology has emerged, transforming the game entirely - laser marking. This innovative method has revolutionized industries relying on plastics such as ABS, PP, PVC, PET, PC, and Nylon, offering unparalleled precision, efficiency, and durability.

Consulting products

- Product Description

- Parameter

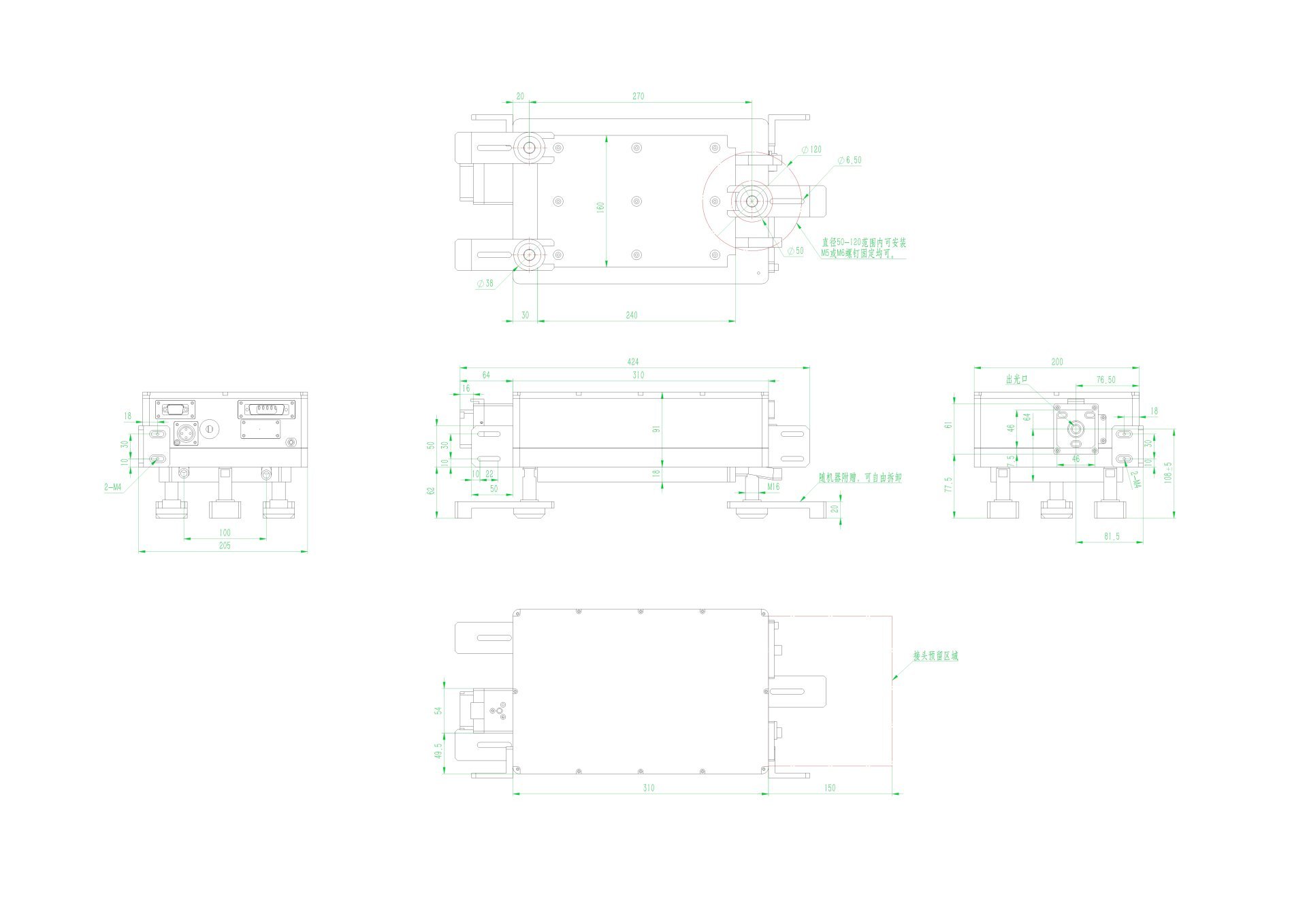

- Dimensional Drawing

- Application Field

-

- Commodity name: Laser Marking On Plastics Used In Industry Such As ABS, PP, PVC, PP, PET, PC, Nylon

- Commodity ID: 1041772479862628352-3

In the realm of industrial plastics, where durability meets functionality, a groundbreaking technology has emerged, transforming the game entirely - laser marking. This innovative method has revolutionized industries relying on plastics such as ABS, PP, PVC, PET, PC, and Nylon, offering unparalleled precision, efficiency, and durability.

Laser Marking on Plastics used in industry such as ABS, PP, PVC, PP, PET, PC, Nylon

Revolutionizing Industrial Plastics: Unveiling the Power of Laser Marking

In the realm of industrial plastics, where durability meets functionality, a groundbreaking technology has emerged, transforming the game entirely - laser marking. This innovative method has revolutionized industries relying on plastics such as ABS, PP, PVC, PET, PC, and Nylon, offering unparalleled precision, efficiency, and durability.

Laser marking on industrial plastics unveils a world of limitless possibilities, catering to a wide range of applications. From automotive components to electronics and medical devices, lasers have become the tool of choice for branding, identification, and traceability. The seamless interaction between lasers and industrial plastics opens doors to creativity and innovation that were previously unimaginable.

Let us delve into the realm of ABS, a popular thermoplastic polymer widely used in various industries. Traditional methods of marking ABS, such as printing or labels, often fall short in terms of durability and permanence. However, laser marking on ABS offers a transformative solution. With its precision and focused heat, the laser interacts with the surface of ABS plastic, creating permanent, high-quality marks that withstand the test of time. This enhances traceability, assists in quality control, and ensures a professional appearance throughout the product's lifecycle.

Similarly, laser marking on PP (polypropylene) has become a game-changer across industries due to its exceptional chemical resistance and lightweight nature. PP finds extensive use in food packaging, automotive parts, and medical devices. By harnessing the power of lasers, manufacturers can mark crucial information like expiration dates, batch codes, or logos directly onto the surface of PP plastic. The laser ensures precise and long-lasting marks, overcoming challenges associated with adhesion and durability that other marking techniques may face.

Moving on to PVC (polyvinyl chloride), another prominent industrial plastic, laser marking offers an ideal solution to meet branding and product identification needs. PVC is widely utilized in signage, electrical cables, and piping systems. With laser marking, graphics, texts, and barcodes can be intricately engraved onto the PVC's surface. This not only yields a sophisticated appearance but also ensures that the marks remain intact, resisting harsh environmental conditions and the test of time.

PET (polyethylene terephthalate) plastic, commonly employed in beverage bottles, textiles, and the packaging industry, has also embraced laser marking as a superior marking method. The laser interacts with the PET plastic, creating deep, permanent marks without compromising the material's integrity. This allows for precise and indelible identification codes, ensuring reliable tracking and enhancing security measures.

Among the array of industrial plastics, PC (polycarbonate) stands out for its exceptional strength, transparency, and heat resistance, making it a preferred choice for various applications, including automotive parts, optical lenses, and electronics. With laser marking technology, manufacturers can imprint logos, serial numbers, or safety information onto PC plastic. The laser's precision and controlled heat generate high-quality marks that exhibit clarity and longevity without compromising the material's inherent properties.

Lastly, laser marking on Nylon, renowned for its exceptional mechanical strength and resistance to wear, has brought a new dimension of possibilities to industries such as aerospace, automotive, and consumer goods. By harnessing the laser's power, manufacturers can permanently mark intricate designs, part numbers, or instructions onto the surface of Nylon materials. The result is a combination of durability, clarity, and precision that exceeds traditional marking methods.

In conclusion, the marriage of laser technology and industrial plastics such as ABS, PP, PVC, PET, PC, and Nylon has paved the way for transformative advancements. Laser marking offers limitless possibilities in terms of durability, precision, and efficiency. By harnessing the power of lasers, manufacturers ensure legible, permanent marks that withstand harsh conditions, enhance traceability, and elevate product branding. Embrace the extraordinary potential of laser marking and witness the industrial plastic landscape evolve into a realm of endless opportunities.

To meet the market demand, RFH newly developed S9 series UV laser . Comparing with its kinds, S9 series UV laser features with rugged sealed cavity, extremely compact size, simple and robust, high stability, high efficiency, high reliability and excellent laser beam quality.Its compact design suggests no necessity in building big light path, which greatly reduces space and cost and makes it easy to be installed into UV laser marking machines. In addition, S9 series cavity structure is more stability and more excellent scalability, which means the same laser cavity can be produces multi-power lasers , and the stability of different power ranges is greatly improved.

Key words:- Laser Marking On Plastics

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体