355nm Nanosecond UV Laser Engraved Ceramic Cup

Release time:2021/09/15

355nm Nanosecond UV Laser Engraved Ceramic Cup

Forging Artistry: Unleashing the Sublime Beauty of Ceramic Cups with 355nm Nanosecond UV Laser Engraving

Ceramic cups have long captivated our senses, offering a vessel that not only indulges our thirst but also elevates our drinking experience to a realm of elegance and sophistication. With the advent of 355nm nanosecond UV laser engraving technology, this ancient vessel of beverage has been bestowed with a remarkable transformation, transcending its humble origins and becoming an exquisite canvas for artistic expression.

The introduction of 355nm nanosecond UV laser engraving on ceramic cups has revolutionized traditional craftsmanship, ushering in an era where creativity finds its zenith. Unlike conventional methods that relied on time-consuming and imprecise techniques, this cutting-edge laser technology enables artisans to etch their visions with unparalleled precision, breathing life into the surface of ceramic cups and transforming them into true works of art.

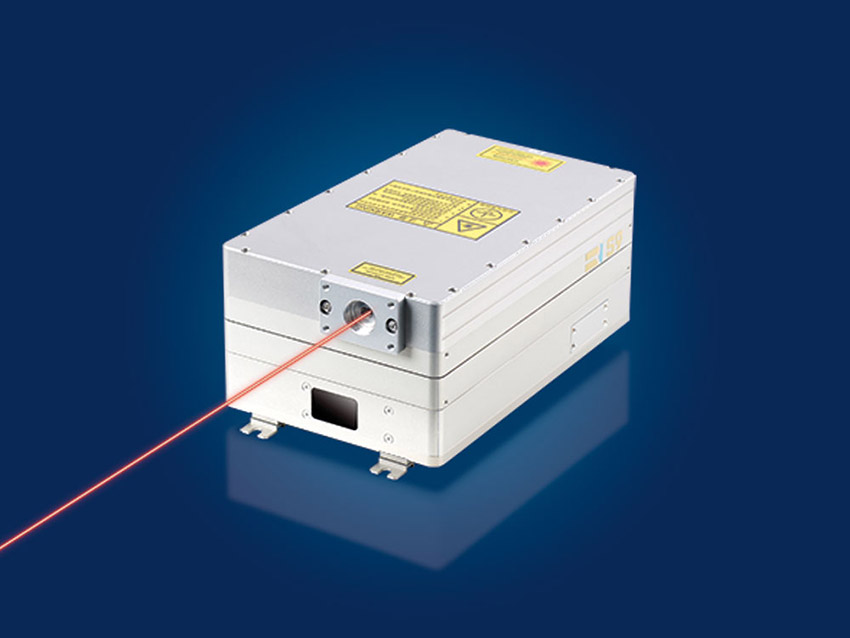

At the core of this remarkable leap in artistic possibility lies the enthralling power of the 355nm UV laser beam. Emitting a swift and focused light, this laser source possesses a wavelength ideally suited for engraving on ceramic surfaces. Its unique ability to interact with ceramic material intricately sculpts the surface, resulting in mesmerizing patterns, intricate textures, and aesthetically captivating designs that entrance the beholder.

The precision afforded by 355nm nanosecond UV laser engraving on ceramic cups is simply unrivaled. This transformative technology bestows artisans with the ability to engrave intricate motifs, elegant lettering, and captivating images that surpass the boundaries of traditional methods. Every stroke of the laser is a symphony of artistry, delivering impeccable lines, delicate curves, and a level of detail that transcends imagination.

But beyond its precision, 355nm nanosecond UV laser engraving on ceramic cups offers a world of endless artistic possibilities. This technology effortlessly adapts to a variety of ceramic compositions and glazes, allowing artists to explore a vast spectrum of visual effects. Whether it be subtle and understated engravings on smooth glossy surfaces or bold and striking designs on matte finishes, this exceptional laser technology acts as an extension of the artist's skill and imagination, providing a limitless realm of creative expression.

The durability of 355nm nanosecond UV laser engraving on ceramic cups further testifies to its prowess. Unlike prints or coatings that fade over time, the laser-engraved designs on ceramic cups become an indelible part of their essence. These intricate engravings exhibit remarkable resistance to scratching, fading, and degradation, ensuring their longevity and enabling them to withstand the test of time. Each sip taken from a laser-engraved ceramic cup becomes a poetic experience, as the artistry etched upon it persists and enchants for years to come.

Moreover, 355nm nanosecond UV laser engraving on ceramic cups exemplifies the harmony between innovation and environmental consciousness. With no harmful chemicals or excessive waste involved in the engraving process, this technology stands as a beacon of sustainability. By harnessing the power of the precisely calibrated UV laser, artisans can unleash their creativity while promoting a greener future, reducing their ecological footprint one masterpiece at a time.

In conclusion, 355nm nanosecond UV laser engraving has propelled the artistry of ceramic cups to new heights, allowing imagination to run wild on this exquisite canvas. Its ability to merge precision, versatility, durability, and sustainability sets a new standard for the industry. With this remarkable technology, artisans can transform mere ceramic cups into vessels of enchantment, where every sip is accompanied by an experience that transcends aesthetics. The marriage of ancient craftsmanship and modern innovation has birthed a renaissance in ceramic cup engraving, where excellence knows no bounds, and artistic expression finds its purest form.

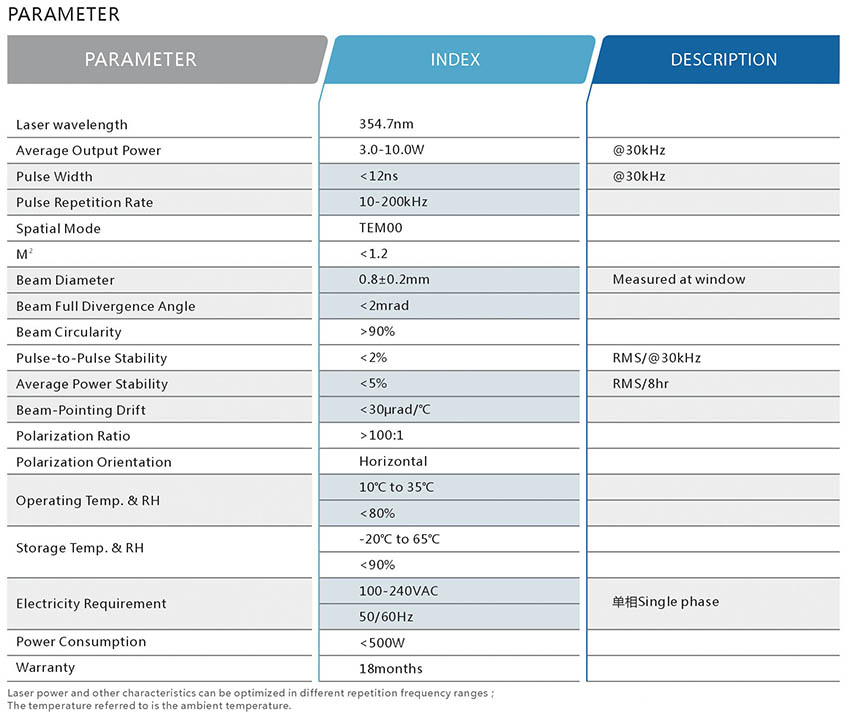

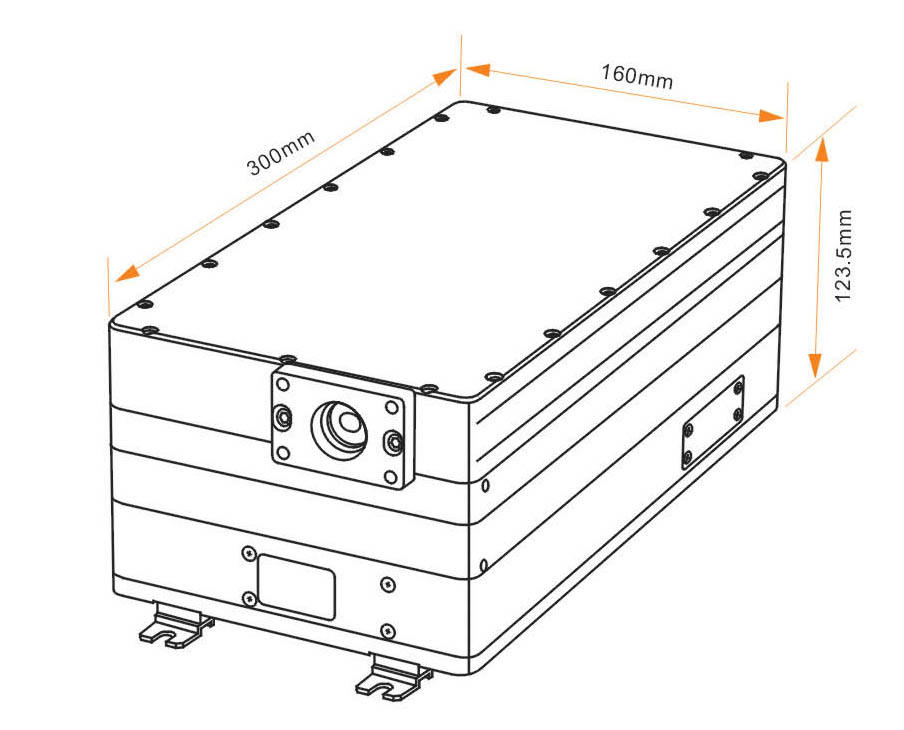

S9-Y series solid state pulsed UV laser is ultra compact. The whole part of power supply is integrated into the laser head. This makes the size of the laser more smaller, and the integration into a system more easier and convenient. S9-Y series is of short pulse width(<12ns@30k),superior beam quality(M²<1.2) and perfect laser sport quality(beam circularity>90%).

S9-Y series uv laser characteristics:

1. 355 nm output wavelength, Up to 200 Hz repetition rate; laser power ranging from 3w-10w; Continuous tuning of repetition rate while maintaining constant pulse energy, superior beam pointing and energy stability make the S9-Y the first choice for micromachining, marking and thin film removal applications

2. Exceptional beam quality (M²<1.2) ,absolutely assured in all repetition rates; relatively short pulse width <12ns@30 with little heat transfer to surrounding material; perfect beam spot quality(Beam Circularity>90%)

Close to Gaussian smooth beam profile with low value M² < 1.2 and good focusability are beneficial for applications such as

3. Unique Q-switching technology, adapts a variety of control requirements of laser applications;Online refreshment for harmonic coupling technology;Excellent long term power stability Rugged sealed cavity, Extremely compact size, Simple and robust

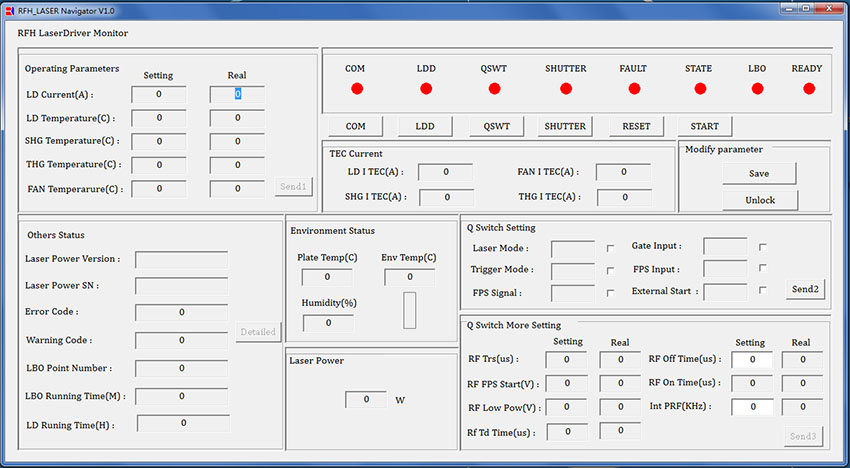

4. Digital control technology for the driver, RS232 control interface ensures easy control and integration with laser marking equipment

5. This laser adopts one - style design with compact and reasonable structure, easy installation.

Easy to transport and saves space due to compact and light design

Water cooling,cost-effective and reliable end-pumping technology and amplifier-free DPSS design guarantee easy operation and alignment simple installation and low maintenance costs

6. Industrial production process control technology,provides quality stable products.

RFH - The leading industrial solid-state laser manufacturer

For over 13 years with excellent long term stability and exceptional good beam quality

Production in dust-free plant & rigorous quality control system

From purchasing, pre-production quality check, assembling, finished product testing, warehouse-in inspection, pre-delivery testing to after-sales service, each step is under control to make sure product quality and consistency in both machine parameters and actual running parameters. This is what makes RFH laser lasts longer than its peers.

The whole part of power supply is integrated into the laser head

Core components of oversea brands with guaranteed quality

Pumping, Q-switching and other core components adopt oversea brands. Work with top brand component suppliers of home and abroad. Each component is guaranteed with its quality from the beginning of materials purchasing. This is why users can trust RFH laser.

UV laser+cooling system sold in a group

Being client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability.

Full-digital display, supporting communication with computer, capable of laser’s remote control

Each laser developed and produced by RFH can always remain high quality in industrial and extreme conditions of scientific research. With stable beam quality, high efficiency, best cost performance and high reliability, RFH has earned good reputation in different industries at home and abroad. After 12-year development, RFH has become a reputed brand in nanosecond laser industry.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers

关键词: 355nm Nanosecond UV Laser,Engraved Ceramic Cup

中文简体

中文简体