RFH 355nm UV Laser Marking Plastic

Today, I will introduce you to an amazing technology that can express art on plastic in a precise and unique way - 355nm UV laser marking. This high-energy laser is not only capable of forming long-lasting marks on plastic surfaces such as nylon, but is even more striking for the unparalleled sense of personalization and artistry it unleashes.

Consulting products

- Product Description

- Parameter

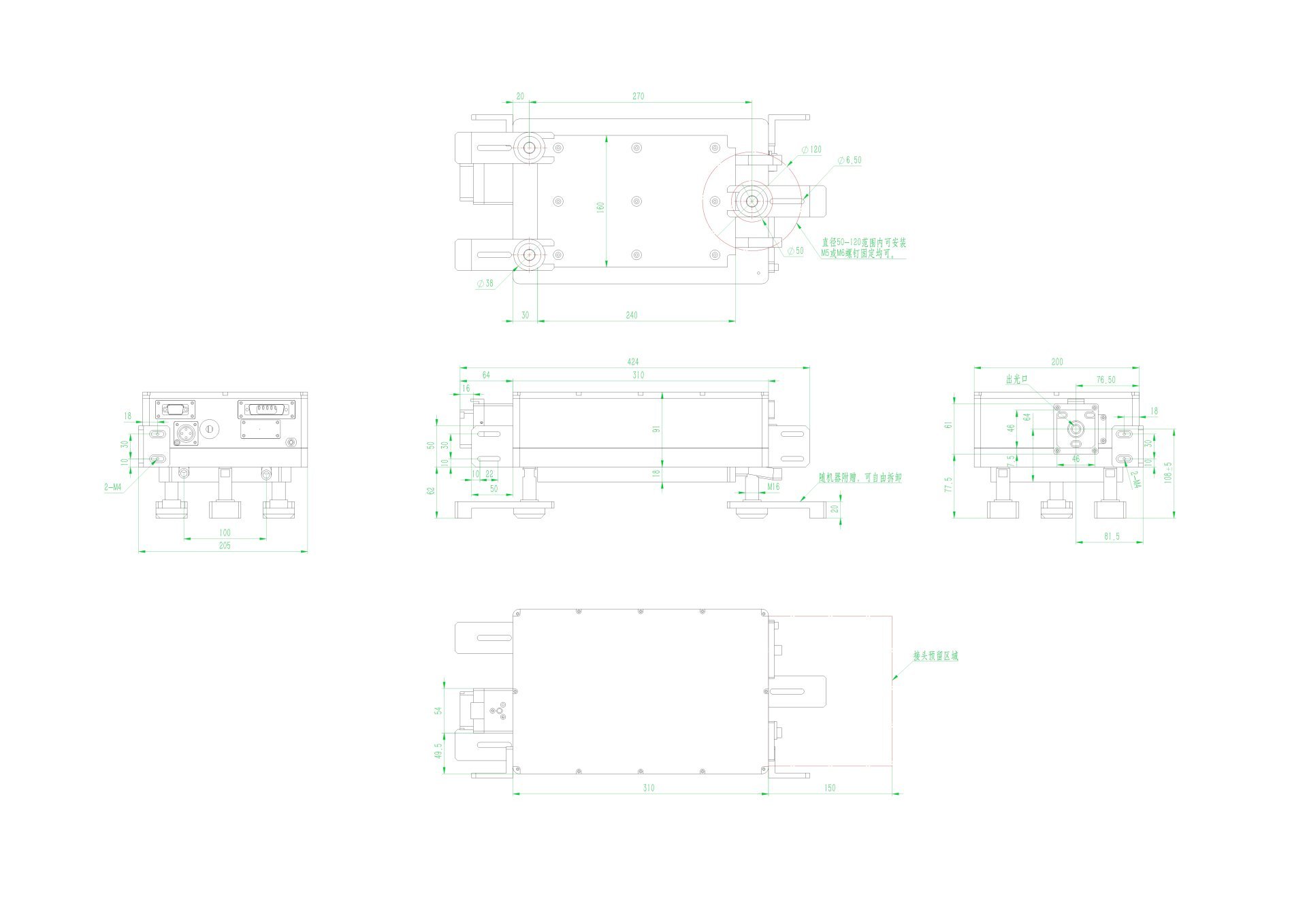

- Dimensional Drawing

- Application Field

-

- Commodity name: RFH 355nm UV Laser Marking Plastic

- Commodity ID: 104177247986

Today, I will introduce you to an amazing technology that can express art on plastic in a precise and unique way - 355nm UV laser marking. This high-energy laser is not only capable of forming long-lasting marks on plastic surfaces such as nylon, but is even more striking for the unparalleled sense of personalization and artistry it unleashes.

355nm UV laser marking plastic

Today, I will introduce you to an amazing technology that can express art on plastic in a precise and unique way - 355nm UV laser marking. This high-energy laser is not only capable of forming long-lasting marks on plastic surfaces such as nylon, but is even more striking for the unparalleled sense of personalization and artistry it unleashes.

Unlike traditional marking methods, 355nm UV lasers take plastic marking to a new level. Its powerful and precise power makes marked results visible and impeccable in detail. Through this disruptive technology, we can express unlimited creativity and imagination in plastics.

The concentrated energy of the 355nm ultraviolet laser is like a silent paintbrush, creating colorful patterns on nylon and other plastics. Whether it is text, patterns or images, they can be accurately and evenly engraved on the plastic surface, making it present a unique and fascinating light and shadow effect. Not only are these markers highly durable, they are also resistant to a variety of environmental elements, allowing them to maintain their glamorous brilliance through everyday use.

It is undeniable that this advanced technology has brought greater possibilities of personalization and artistry to plastic products. Through 355nm ultraviolet laser marking, plastic products can display unique textures and patterns on the surface, highlighting the unique charm and unique artistic value of the brand. Whether it is custom gifts, high-end packaging or industrial products, this innovative marking technology can add a lot of color to the product.

It is worth mentioning that the precision and personalization capabilities of 355nm UV laser marking technology also make it useful in various industries. Whether in the medical industry, the electronics industry or the automotive industry, applications for this technology can be found. For example, marking on medical devices can not only improve the traceability of products, but also increase the uniqueness and brand influence of products. In the electronics industry, this high-precision marking technology can mark clear text and patterns on tiny devices, improving product recognition and aesthetics. In the automotive industry, 355nm UV laser marking can bring higher marking quality and individual style to auto parts.

In general, 355nm UV laser marking technology has opened up exciting new realms for plastic marking. Its precision, individuality and artistic sense allow plastic products to be reborn and show dazzling light. With the continuous development of this technology, we believe that there will be more innovative applications to bring more possibilities to plastic marking, injecting more creativity and unique styles into all walks of life.

RFH F9 series Water cooled UV laser's power range is 3w-5w .Comparing with its kinds, F9 series UV laser features with rugged sealed cavity, extremely compact size, simple and robust, high stability, high efficiency, high reliability and excellent laser beam quality.Its compact design suggests no necessity in building big light path, which greatly reduces space and cost and makes it easy to be installed into UV laser marking machines. In addition, F9 series cavity structure has more stability and more excellent scalability, which means the same laser cavity can produce multi-power lasers , and the stability of different power ranges is greatly improved.

Key words:- 355nm UV lasers

- Laser Marking Plastic

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体