RFH Low-Power Ultraviolet Lasers Paint Removal On Metal

With the advancement of technology and the increase of people's demand for fine processing, low-power ultraviolet lasers have shown great potential in the field of metal surface paint stripping.

Consulting products

- Product Description

- Parameter

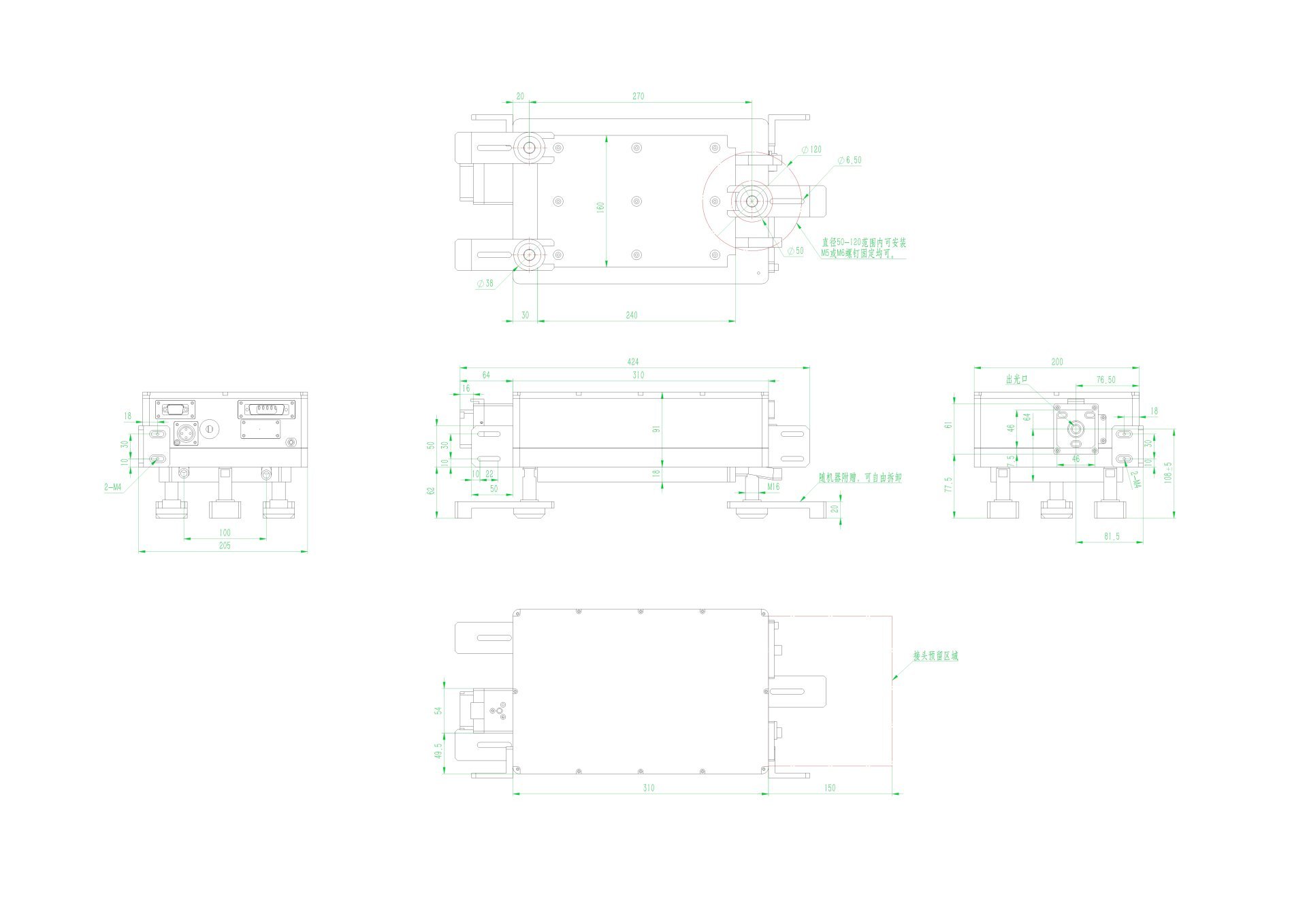

- Dimensional Drawing

- Application Field

-

- Commodity name: RFH Low-Power Ultraviolet Lasers Paint Removal On Metal

- Commodity ID: 10417724

With the advancement of technology and the increase of people's demand for fine processing, low-power ultraviolet lasers have shown great potential in the field of metal surface paint stripping.

RFH low-power ultraviolet lasers paint removal on metal

With the advancement of technology and the increase of people's demand for fine processing, low-power ultraviolet lasers have shown great potential in the field of metal surface paint stripping.

Metal stripping is a common process aimed at restoring the original luster and beauty of metal. However, traditional methods of stripping paint are time- and labor-intensive and can cause damage to the metal surface. The emergence of low-power ultraviolet lasers provides a new solution for this process.

Low power UV lasers are a key tool in the paint stripping process due to their unique characteristics and controllability. It acts like a precise carving knife, precisely peeling off the paint layer from the metal surface without damaging the metal surface. This not only improves work efficiency, but also reduces wear and tear on metal materials.

The use of low-power UV lasers for metal surface stripping can better control the depth and area of stripping and reduce environmental pollution. Compared with traditional paint strippers, UV lasers do not need to use chemical solvents, avoiding the generation and release of harmful substances, and are environmentally friendly.

In addition, low-power UV lasers have the advantage of being fast and efficient. Its high-speed operation and precise scale adjustment make the metal surface paint stripping work easier and more efficient. Compared with traditional manual operation, ultraviolet laser can greatly reduce manual errors and labor intensity, and improve production efficiency.

The development prospect of low-power ultraviolet laser in the field of metal surface paint stripping is broad. It not only brings more advanced technology to the metal processing industry, but also provides users with higher quality products and services. In the future, we can foresee that low-power ultraviolet lasers will play a greater role in the field of metal surface paint stripping, bringing more possibilities for industry development and innovation.

RFH F9 series Water cooled UV laser's power range is 3w-5w .Comparing with its kinds, F9 series UV laser features with rugged sealed cavity, extremely compact size, simple and robust, high stability, high efficiency, high reliability and excellent laser beam quality.Its compact design suggests no necessity in building big light path, which greatly reduces space and cost and makes it easy to be installed into UV laser marking machines. In addition, F9 series cavity structure has more stability and more excellent scalability, which means the same laser cavity can produce multi-power lasers , and the stability of different power ranges is greatly improved.

Key words:- Low-Power Ultraviolet Lasers

- Lasers Paint Removal On Metal

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体