German customers purchase RFH 10W UV laser to scribe on wafers

In today's highly information-based era, various industries are pursuing higher accuracy and efficiency. Among them, laser technology plays an increasingly important role in many fields with its unique advantages. German customers chose to purchase the RFH10W UV laser for scribing on wafers, achieving precise, accurate and detailed processing results.

Consulting products

- Product Description

- Parameter

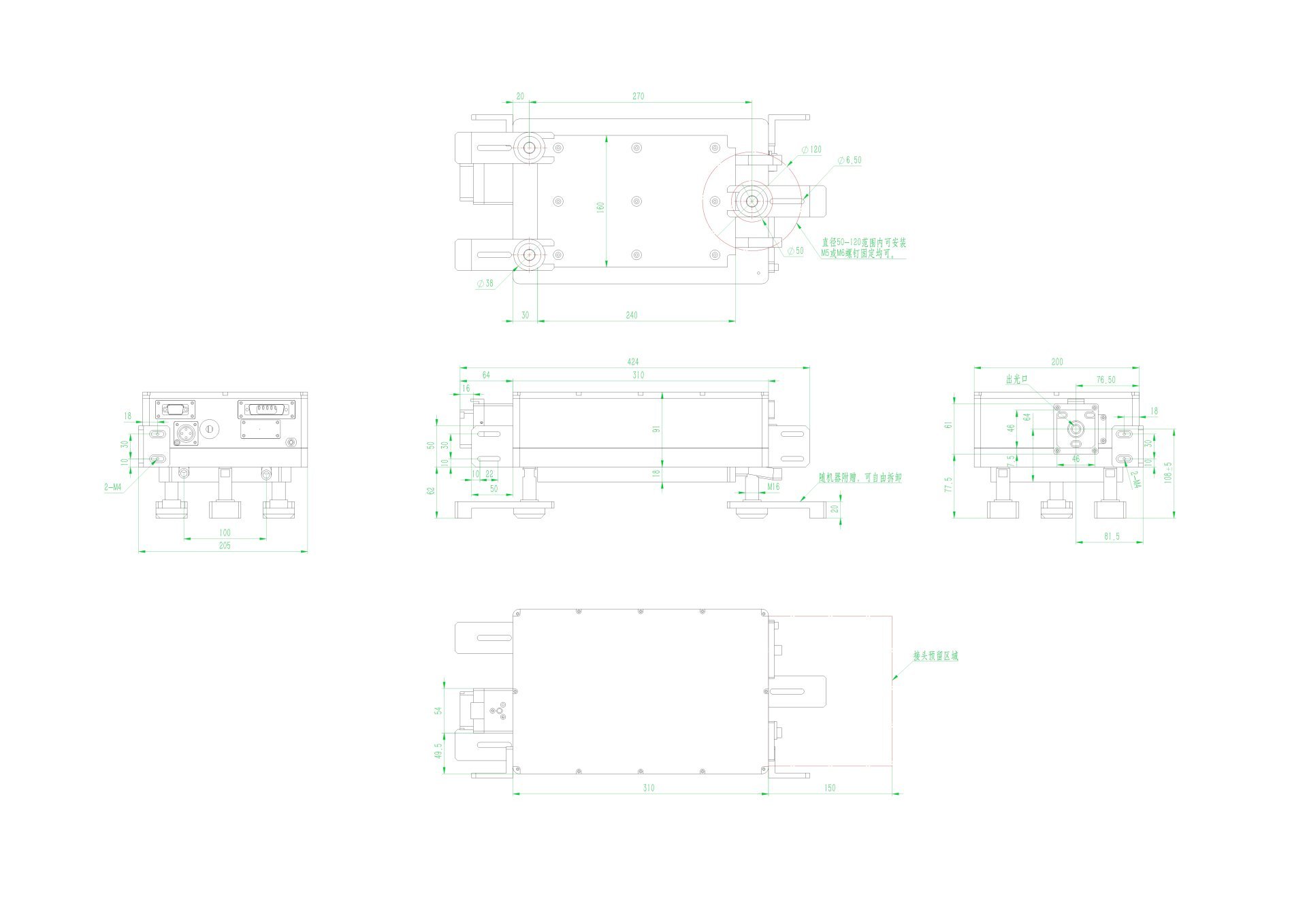

- Dimensional Drawing

- Application Field

-

- Commodity name: German customers purchase RFH 10W UV laser to scribe on wafers

- Commodity ID: 10172431-01012

In today's highly information-based era, various industries are pursuing higher accuracy and efficiency. Among them, laser technology plays an increasingly important role in many fields with its unique advantages. German customers chose to purchase the RFH10W UV laser for scribing on wafers, achieving precise, accurate and detailed processing results.

German customers purchase RFH10W UV laser to scribe on wafers to achieve precise, accurate and detailed processing

In today's highly information-based era, various industries are pursuing higher accuracy and efficiency. Among them, laser technology plays an increasingly important role in many fields with its unique advantages. German customers chose to purchase the RFH10W UV laser for scribing on wafers, achieving precise, accurate and detailed processing results.

The RFH10W UV laser adopts advanced laser technology and has the characteristics of high precision, high speed and high stability. It can scribe micron-level lines on the wafer surface, and the lines drawn are smooth, continuous and precise. This kind of laser is widely used in semiconductors, integrated circuits and other fields, and is an important tool for achieving precise, accurate and detailed processing.

In the specific application scenario of the German customer, it is necessary to draw high-precision, continuous lines with a certain depth. The RFH10W UV laser successfully meets customer needs with its excellent performance. The drawn lines are smooth, continuous and precise, like an invisible knife, achieving precise, accurate and fine processing effects.

During the processing process, the RFH10W UV laser demonstrated extremely high stability and reliability. Even under long-term working conditions, its performance remains stable, ensuring production efficiency and product quality. In addition, the laser also has the characteristics of high efficiency and high precision, which effectively reduces production costs.

In short, the RFH10W ultraviolet laser has once again proved the important position of laser technology in modern processing with its precise, accurate and detailed processing results and efficient and stable performance in the wafer scribing application of German customers. With the continuous development of technology, we have reason to believe that laser technology will play an even more important role in the future.

Key words:- 10W UV laser

- scribe on wafers

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体