Customer purchased RFH 10W UV laser to mark patterns on ceramics

In today's industrial world, laser marking technology has become an important production process. Among them, RFH 10W UV laser has been widely used due to its unique characteristics and superior performance. This article will introduce in detail the process and results of customers purchasing RFH 10W UV laser to mark patterns on ceramics.

Consulting products

- Product Description

- Parameter

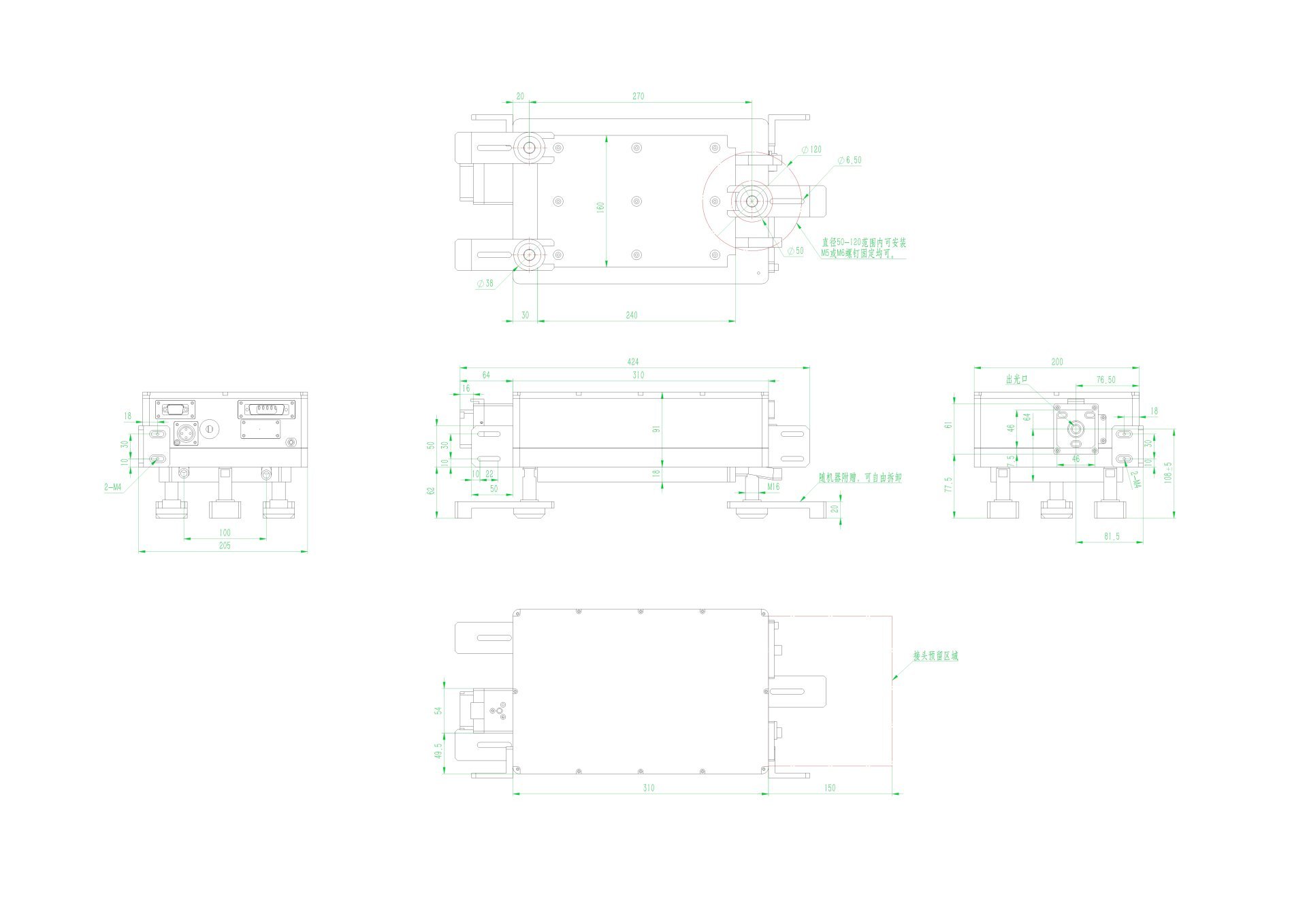

- Dimensional Drawing

- Application Field

-

- Commodity name: Customer purchased RFH 10W UV laser to mark patterns on ceramics

- Commodity ID: 1041772479862628351-0

In today's industrial world, laser marking technology has become an important production process. Among them, RFH 10W UV laser has been widely used due to its unique characteristics and superior performance. This article will introduce in detail the process and results of customers purchasing RFH 10W UV laser to mark patterns on ceramics.

Customer purchased RFH 10W UV laser to mark patterns on ceramics

In today's industrial world, laser marking technology has become an important production process. Among them, RFH 10W UV laser has been widely used due to its unique characteristics and superior performance. This article will introduce in detail the process and results of customers purchasing RFH 10W UV laser to mark patterns on ceramics.

First, you need to understand the principles and characteristics of the RFH 10W UV laser. The RFH ultraviolet laser uses high-energy pulses to instantly heat the ceramic surface until it melts or vaporizes, forming exquisite marking patterns. This laser has the advantages of high precision, high speed, and high stability, and can form permanent marks on the surface of ceramics without causing any damage to the ceramic itself.

There are many reasons why customers purchase RFH 10W UV lasers. First of all, this laser has a wide range of applications and can be used for surface marking of various materials, including metal, plastic, glass, ceramics, etc. Secondly, the laser has excellent performance and can meet customers' requirements for high precision, high speed and high stability. In addition, the price of RFH UV lasers is also relatively reasonable and will not put excessive economic pressure on customers.

After purchasing the RFH 10W UV laser, customers need to make certain preparations. First of all, customers need to understand the usage and precautions of the laser to ensure that no unexpected situations occur during use. Secondly, customers need to choose the appropriate software and control system according to their own needs to achieve automated marking and control. Finally, customers need to pre-treat the ceramic surface, such as cleaning and drying, to ensure that the marking effect is more beautiful and lasting.

After completing the preparation work, the customer can start the marking operation. Generally speaking, the marking operation is relatively simple. You only need to connect the RFH 10W UV laser to the computer and use the control software to select the appropriate pattern and parameters. During the marking process, customers need to pay attention to the operating status of the laser and the changes in the ceramic surface to ensure marking quality and safety.

After a period of study and practice, customers will be able to master the marking skills and essentials of the RFH 10W UV laser. Through continuous practice and application, customers can not only improve their skill levels, but also improve production efficiency and product quality.

In short, the RFH 10W UV laser is an excellent marking equipment with broad application prospects and market prospects. By purchasing and using this equipment, customers can not only improve their production efficiency and product quality, but also meet market needs and consumer expectations. In future industrial development, RFH UV lasers will play a more important role.

As the leading industrial solid-state laser manufacturer, RFH laser company offer 355nm ultraviolet laser, 532nm green laser and customized laser for a broad range of commercial, industrial, and scientific applications.

After 16 years of development, RFH now has an industrial laser oriented R&D team made up of top professionals and experts from both home and abroad. Its R&D departments cover engineering, laser and electric. In addition, RFH has obtained 15 national patent certificates and 14 software copyright certificates and is certified as “High Tech Enterprise”, “Shenzhen High Tech Enterprise” and “Software Enterprise” as well as the council member of Guangdong 3D Printing Industry Innovation League and Guangdong Laser Industry Association.

Key words:

Key words:- 10W UV laser

- mark patterns on ceramics

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体