355nm UV Nanosecond Laser Cuts Medical Implantable Chips

Ultraviolet nanosecond lasers seem to have become a dark horse in the field of medical technology today, and have exerted great potential and advantages in cutting medical implantable chips. With its unique features and excellent performance, it is gradually becoming an important tool in the medical industry.

Consulting products

- Product Description

- Parameter

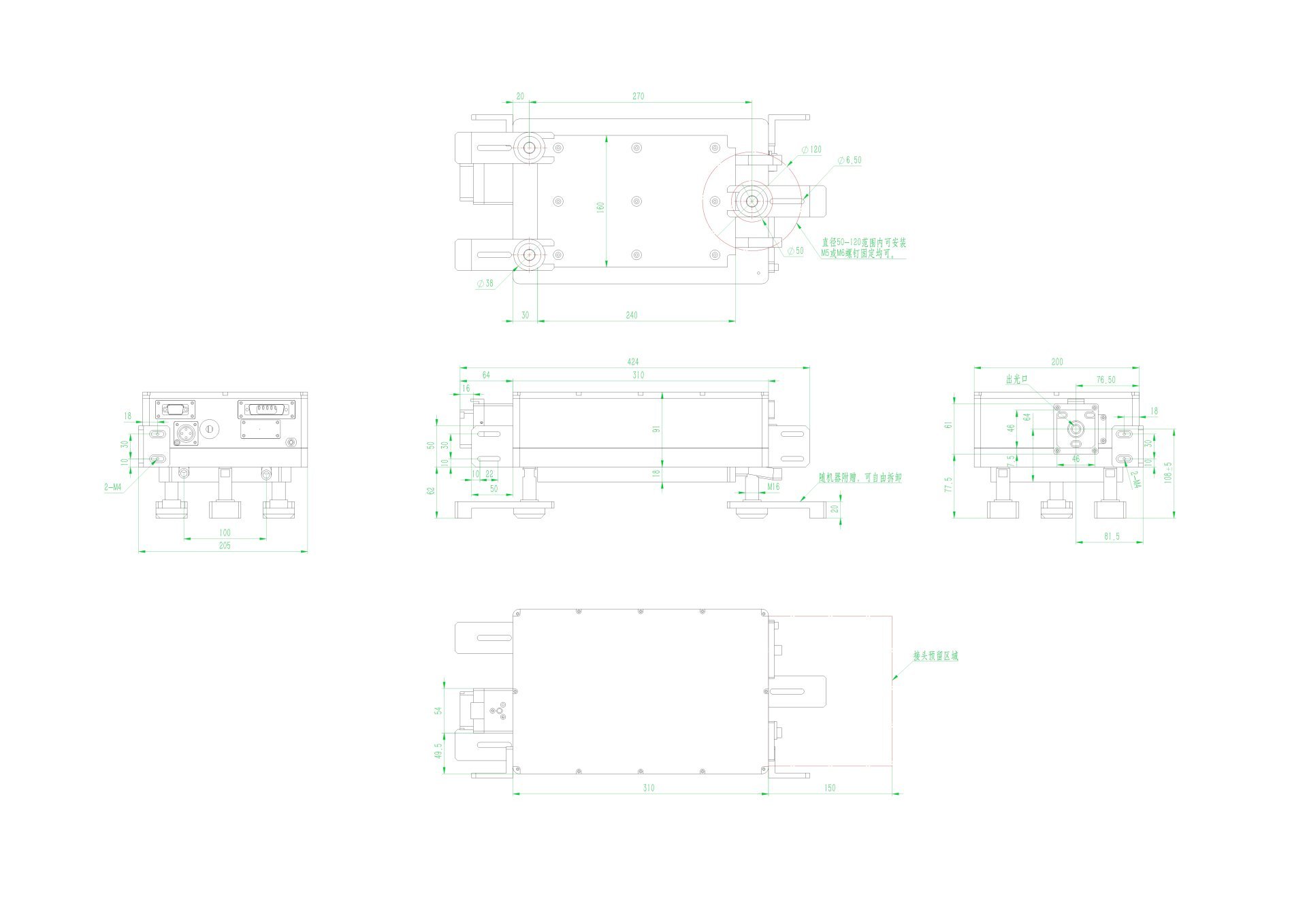

- Dimensional Drawing

- Application Field

-

- Commodity name: 355nm UV Nanosecond Laser Cuts Medical Implantable Chips

- Commodity ID: 1041772479862

Ultraviolet nanosecond lasers seem to have become a dark horse in the field of medical technology today, and have exerted great potential and advantages in cutting medical implantable chips. With its unique features and excellent performance, it is gradually becoming an important tool in the medical industry.

UV Nanosecond Laser Cuts Medical Implantable Chips

Ultraviolet nanosecond lasers seem to have become a dark horse in the field of medical technology today, and have exerted great potential and advantages in cutting medical implantable chips. With its unique features and excellent performance, it is gradually becoming an important tool in the medical industry.

Traditional medical implantable chip dicing methods often involve mechanical or chemical dicing processes, but these methods undoubtedly have some challenges-such as waste, limited precision, and possible damage to the chip structure. However, the emergence of ultraviolet nanosecond lasers upended this situation.

With the characteristics of extremely short pulse width and high energy output, ultraviolet nanosecond laser can realize precise and efficient non-contact cutting, which brings new possibilities for the production of medical implantable chips. Compared with traditional methods, it is not only more efficient, but also can precisely control the cutting position and shape, avoiding possible risks to the chip structure.

In addition, the ultraviolet nanosecond laser also has high optical resolution and energy density, so it can achieve micron-level cutting accuracy without excessive thermal impact on the chip material, ensuring the stability and reliability of the chip.

With the continuous advancement of science and technology, ultraviolet nanosecond lasers will continue to develop and improve in the field of medical implantable chips. In the future, we can foresee that UV nanosecond lasers will achieve higher cutting speeds, making the production process more efficient and flexible. At the same time, the automated and intelligent paint stripping process will also become a development trend, making the production of medical implantable chips more intelligent and convenient.

In summary, UV nanosecond lasers have shown great potential and advantages in cutting medical implantable chips. Its efficient and precise cutting ability will greatly promote the development of medical technology and bring more benefits to people's health and life. It is believed that in the near future, UV nanosecond lasers will become an indispensable weapon in the medical industry and bring us a better tomorrow.

To meet the market demand, RFH newly developed S9 series solid state pulsed UV laser in 2020. Comparing with its kinds, S9 series solid state pulsed UV laser features more compact and delicate design with more stable laser output.Its compact design suggests no necessity in building big light path, which reduces space and cost to a great extent and makes it easy to be installed into flying laser marking machines. In addition, S9 series UV laser has more stable laser cavity of better extensibility, which means the same laser cavity can be made into lasers of different powers whose stability are greatly improved.

To meet the market demand, RFH newly developed S9 series solid state pulsed UV laser in 2020. Comparing with its kinds, S9 series solid state pulsed UV laser features more compact and delicate design with more stable laser output.Its compact design suggests no necessity in building big light path, which reduces space and cost to a great extent and makes it easy to be installed into flying laser marking machines. In addition, S9 series UV laser has more stable laser cavity of better extensibility, which means the same laser cavity can be made into lasers of different powers whose stability are greatly improved. S9 series uv laser characteristics:1. Laser wavelength at 354.7nm, repetition rates cover a wide range(single pulse to 200kHz); laser power ranging from 3.0w-5.0w;2. Exceptional beam quality (M²<1.2) ,absolutely assured in all repetition rates; relatively short pulse width <12ns@30 with little heat transfer to surrounding material; perfect beam spot quality(Beam Circularity>90%)3. Unique Q-switching technology, adapts a variety of control requirements of laser applications;Online refreshment for harmonic coupling technology;Excellent long term power stability4. Digital control technology for the driver, enables user to command through RS2325. This laser adopts one - style design with compact and reasonable structure, easy installation.6. Industrial production process control technology,provides quality stable products.RFH - The leading industrial solid-state laser manufacturerFor over 13 years with excellent long term stability and exceptional good beam qualityProduction in dust-free plant & rigorous quality control systemFrom purchasing, pre-production quality check, assembling, finished product testing, warehouse-in inspection, pre-delivery testing to after-sales service, each step is under control to make sure product quality and consistency in both machine parameters and actual running parameters. This is what makes RFH laser lasts longer than its peers.

S9 series uv laser characteristics:1. Laser wavelength at 354.7nm, repetition rates cover a wide range(single pulse to 200kHz); laser power ranging from 3.0w-5.0w;2. Exceptional beam quality (M²<1.2) ,absolutely assured in all repetition rates; relatively short pulse width <12ns@30 with little heat transfer to surrounding material; perfect beam spot quality(Beam Circularity>90%)3. Unique Q-switching technology, adapts a variety of control requirements of laser applications;Online refreshment for harmonic coupling technology;Excellent long term power stability4. Digital control technology for the driver, enables user to command through RS2325. This laser adopts one - style design with compact and reasonable structure, easy installation.6. Industrial production process control technology,provides quality stable products.RFH - The leading industrial solid-state laser manufacturerFor over 13 years with excellent long term stability and exceptional good beam qualityProduction in dust-free plant & rigorous quality control systemFrom purchasing, pre-production quality check, assembling, finished product testing, warehouse-in inspection, pre-delivery testing to after-sales service, each step is under control to make sure product quality and consistency in both machine parameters and actual running parameters. This is what makes RFH laser lasts longer than its peers. Top professional team, independent R&D in laser oriented power supply control systemThere is a one-to-one correspondence between power supply and laser. The stability of power supply control system determines if the laser can maximize its performance during operation. RFH Laser has independent R&D in power supply technique which enables timely update and improvement of power supply control system module based on the laser’s need. 12-year experience in R&D and a top professional team make RFH laser a reliable and stable laser system.

Top professional team, independent R&D in laser oriented power supply control systemThere is a one-to-one correspondence between power supply and laser. The stability of power supply control system determines if the laser can maximize its performance during operation. RFH Laser has independent R&D in power supply technique which enables timely update and improvement of power supply control system module based on the laser’s need. 12-year experience in R&D and a top professional team make RFH laser a reliable and stable laser system. Core components of oversea brands with guaranteed qualityPumping, Q-switching and other core components adopt oversea brands. Work with top brand component suppliers of home and abroad. Each component is guaranteed with its quality from the beginning of materials purchasing. This is why users can trust RFH laser.

Core components of oversea brands with guaranteed qualityPumping, Q-switching and other core components adopt oversea brands. Work with top brand component suppliers of home and abroad. Each component is guaranteed with its quality from the beginning of materials purchasing. This is why users can trust RFH laser. Small size, cost saving, ease of installationComparing with its kind, RFH laser has smaller size, more stable laser cavity and better extensibility with space saving, which makes it easy to be installed into flying laser marking machine in order to save costs for users.

Small size, cost saving, ease of installationComparing with its kind, RFH laser has smaller size, more stable laser cavity and better extensibility with space saving, which makes it easy to be installed into flying laser marking machine in order to save costs for users. Power supply+laser head+cooling system sold in a groupBeing client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability.

Power supply+laser head+cooling system sold in a groupBeing client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability. Full-digital display, supporting communication with computer, capable of laser’s remote control

Full-digital display, supporting communication with computer, capable of laser’s remote control Each laser developed and produced by RFH can always remain high quality in industrial and extreme conditions of scientific research. With stable beam quality, high efficiency, best cost performance and high reliability, RFH has earned good reputation in different industries at home and abroad. After 12-year development, RFH has become a reputed brand in nanosecond laser industry.Key words:

Each laser developed and produced by RFH can always remain high quality in industrial and extreme conditions of scientific research. With stable beam quality, high efficiency, best cost performance and high reliability, RFH has earned good reputation in different industries at home and abroad. After 12-year development, RFH has become a reputed brand in nanosecond laser industry.Key words:- Ultraviolet nanosecond lasers

- Cuts Medical Implantable Chips

-

Model S9 UV LASER Parameter Index Unit Description Laser wavelength 354.7 nm Average Output Power 3.0-5.0 W @30kHz Pulse Width <12 ns @30kHz Pulse Repetition Rate 10-200 kHz Spatial Mode TEMoo M2 <1.2 Beam Diameter 0.8±0.2 mm Measured at window Beam Full Divergence Angle <2 mrad Beam Circularity >90 % Pulse-to-Pulse Stability <2 % RMS/@30kHz Average Power Stability <5 % RMS/8hr Beam-Pointing Drift <30 μrad/℃ Polarization Ratio >100:1 Polarization Orientation Horizontal Operating Temp. & RH 10 to 35

<80℃

%Storage Temp. & RH -20 to 65

<90℃

%Electricity Requirement

Power Consumption

100-240

50/60

<500VAC

Hz

WSingle phase Warranty 18

months

中文简体

中文简体