UV Laser Marking Machine Customer Purchases 355nm UV Laser To Remove Metal Surface Coating

A laser marking machine customer in Finland recently attracted the attention of the industry. They decided to purchase a 355nm UV laser to meet the needs of metal surface coating removal. This is a completely new field of application, and the introduction of laser technology has brought unprecedented efficiency and precision to the removal of metal surface coatings.

Consulting products

- Product Description

- Parameter

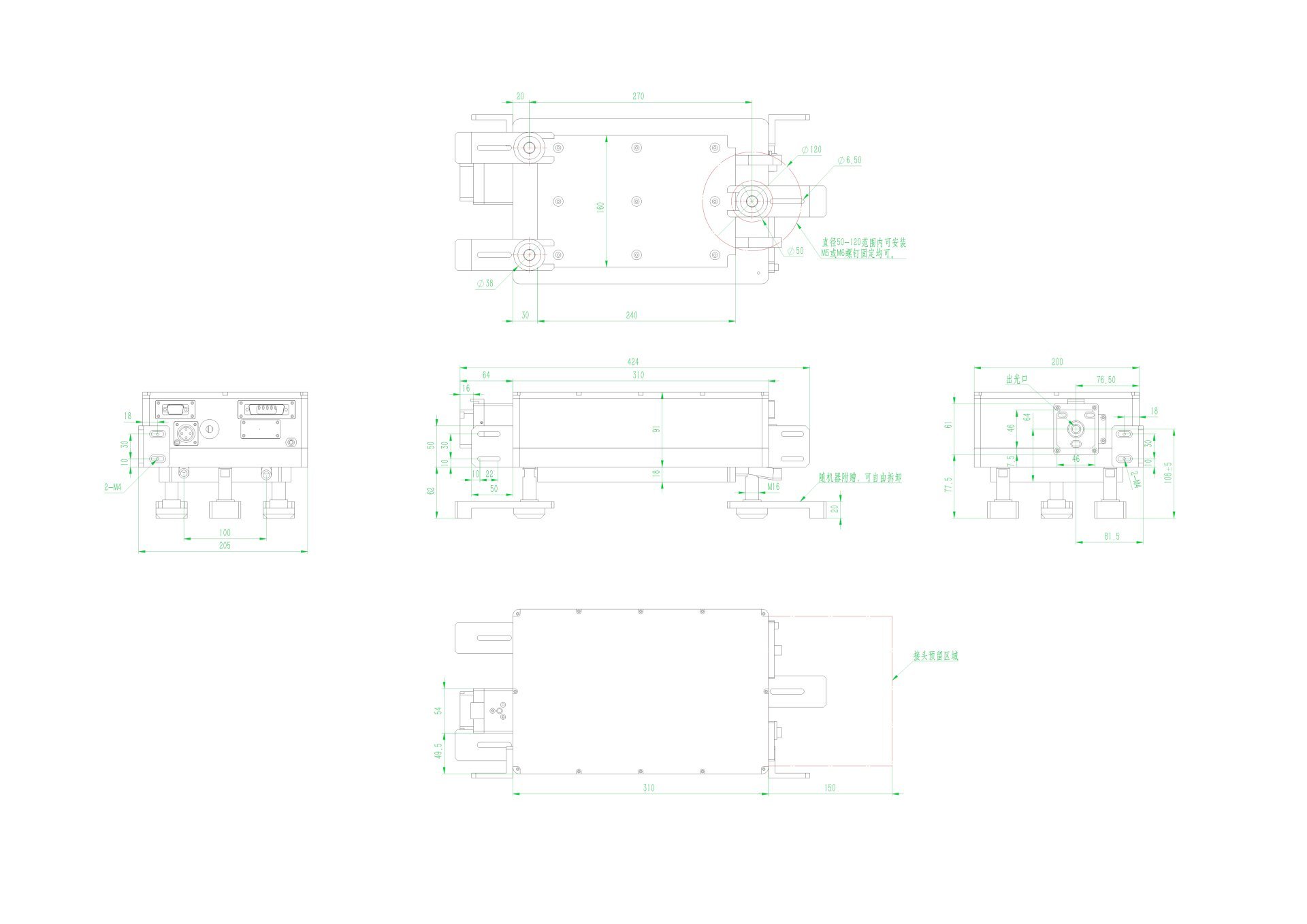

- Dimensional Drawing

- Application Field

-

- Commodity name: UV Laser Marking Machine Customer Purchases 355nm UV Laser To Remove Metal Surface Coating

- Commodity ID: 1041772633

A laser marking machine customer in Finland recently attracted the attention of the industry. They decided to purchase a 355nm UV laser to meet the needs of metal surface coating removal. This is a completely new field of application, and the introduction of laser technology has brought unprecedented efficiency and precision to the removal of metal surface coatings.

Finnish laser marking machine customer purchases 355nm UV laser to remove metal surface coating

A laser marking machine customer in Finland recently attracted the attention of the industry. They decided to purchase a 355nm UV laser to meet the needs of metal surface coating removal. This is a completely new field of application, and the introduction of laser technology has brought unprecedented efficiency and precision to the removal of metal surface coatings.

Metal surface coating plays an important role in protection and beautification in industrial production. However, over time, these coatings may be affected by wear, oxidation, or other factors and require maintenance or replacement. Traditional surface coating removal methods are usually time-consuming and ineffective, and the emergence of laser technology provides a fast and efficient solution to this problem.

The Finnish customer successfully applied the 355nm ultraviolet laser to the metal surface coating removal process by introducing it. The high energy density and short pulse width of this UV laser, combined with excellent beam quality and stability, make precise ablation work feasible and easy.

Through instantaneous high-energy focusing, the ultraviolet laser can evaporate, peel off or peel off the metal surface coating, revealing the original metallic luster. Compared with traditional removal methods, laser technology can better control the processing depth and removal position to avoid unnecessary damage to the substrate. This not only improves work efficiency and quality, but also reduces damage to the environment.

The application of laser technology also brings a series of other advantages. For example, UV lasers are capable of processing many types of metals, such as stainless steel, aluminum alloys, and titanium alloys, making them versatile and flexible. In addition, due to the high reliability and stability of the laser, customers can reduce maintenance costs and equipment downtime, and improve production efficiency and economic benefits.

The Finnish customer's decision is not only to meet the needs of a surface coating removal, but also reflects the keen insight into technological development and the relentless pursuit of high-quality craftsmanship. The application prospects of laser technology in the metal industry are exciting and bring more innovative possibilities for other industries. I believe that the application of lasers in the field of metal surface coating removal will continue to promote the development of the industry and create more business opportunities and value for customers.

Expert III 355 series UV DPSS laser, developed and produced by RFH, covers 10w-15w in laser power with short pulse width (<20ns@40K) ,superior beam quality (M²<1.2) and perfect laser spot quality (beam circularity >90%). It is widely used in PE/PCB/FPC cutting, glass & sapphire cutting, drilling, scribing & cutting used in high precision micromaching areas.

Expert III 355 series UV DPSS laser, developed and produced by RFH, covers 10w-15w in laser power with short pulse width (<20ns@40K) ,superior beam quality (M²<1.2) and perfect laser spot quality (beam circularity >90%). It is widely used in PE/PCB/FPC cutting, glass & sapphire cutting, drilling, scribing & cutting used in high precision micromaching areas. Expert III 355 series uv laser characteristics:1. Laser wavelength at 354.7nm, repetition rates cover a wide range(single pulse to 200kHz); laser power ranging from 10w-15w ;2. Exceptional beam quality (M²<1.2) ,absolutely assured in all repetition rates; relatively short pulse width <20ns@40K with little heat transfer to surrounding material; perfect beam spot quality(Beam Circularity>90%)3. Unique Q-switching technology, adapts a variety of control requirements of laser applications;Online refreshment for harmonic coupling technology;Excellent long term power stability4. Digital control technology for the driver, enables user to command through RS2325. This laser adopts one - style design with compact and reasonable structure, easy installation.6. Industrial production process control technology,provides quality stable products.RFH - The leading industrial solid-state laser manufacturerFor over 13 years with excellent long term stability and exceptional good beam qualityProduction in dust-free plant & rigorous quality control systemFrom purchasing, pre-production quality check, assembling, finished product testing, warehouse-in inspection, pre-delivery testing to after-sales service, each step is under control to make sure product quality and consistency in both machine parameters and actual running parameters. This is what makes RFH laser lasts longer than its peers.

Expert III 355 series uv laser characteristics:1. Laser wavelength at 354.7nm, repetition rates cover a wide range(single pulse to 200kHz); laser power ranging from 10w-15w ;2. Exceptional beam quality (M²<1.2) ,absolutely assured in all repetition rates; relatively short pulse width <20ns@40K with little heat transfer to surrounding material; perfect beam spot quality(Beam Circularity>90%)3. Unique Q-switching technology, adapts a variety of control requirements of laser applications;Online refreshment for harmonic coupling technology;Excellent long term power stability4. Digital control technology for the driver, enables user to command through RS2325. This laser adopts one - style design with compact and reasonable structure, easy installation.6. Industrial production process control technology,provides quality stable products.RFH - The leading industrial solid-state laser manufacturerFor over 13 years with excellent long term stability and exceptional good beam qualityProduction in dust-free plant & rigorous quality control systemFrom purchasing, pre-production quality check, assembling, finished product testing, warehouse-in inspection, pre-delivery testing to after-sales service, each step is under control to make sure product quality and consistency in both machine parameters and actual running parameters. This is what makes RFH laser lasts longer than its peers. Top professional team, independent R&D in laser oriented power supply control systemThere is a one-to-one correspondence between power supply and laser. The stability of power supply control system determines if the laser can maximize its performance during operation. RFH Laser has independent R&D in power supply technique which enables timely update and improvement of power supply control system module based on the laser’s need. 12-year experience in R&D and a top professional team make RFH laser a reliable and stable laser system.

Top professional team, independent R&D in laser oriented power supply control systemThere is a one-to-one correspondence between power supply and laser. The stability of power supply control system determines if the laser can maximize its performance during operation. RFH Laser has independent R&D in power supply technique which enables timely update and improvement of power supply control system module based on the laser’s need. 12-year experience in R&D and a top professional team make RFH laser a reliable and stable laser system. Core components of oversea brands with guaranteed qualityPumping, Q-switching and other core components adopt oversea brands. Work with top brand component suppliers of home and abroad. Each component is guaranteed with its quality from the beginning of materials purchasing. This is why users can trust RFH laser.

Core components of oversea brands with guaranteed qualityPumping, Q-switching and other core components adopt oversea brands. Work with top brand component suppliers of home and abroad. Each component is guaranteed with its quality from the beginning of materials purchasing. This is why users can trust RFH laser. Power supply+laser head+cooling system sold in a groupBeing client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability.

Power supply+laser head+cooling system sold in a groupBeing client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability. Full-digital display, supporting communication with computer, capable of laser’s remote control

Full-digital display, supporting communication with computer, capable of laser’s remote control Each laser developed and produced by RFH can always remain high quality in industrial and extreme conditions of scientific research. With stable beam quality, high efficiency, best cost performance and high reliability, RFH has earned good reputation in different industries at home and abroad. After 12-year development, RFH has become a reputed brand in nanosecond laser industry.Key words:

Each laser developed and produced by RFH can always remain high quality in industrial and extreme conditions of scientific research. With stable beam quality, high efficiency, best cost performance and high reliability, RFH has earned good reputation in different industries at home and abroad. After 12-year development, RFH has become a reputed brand in nanosecond laser industry.Key words:- 55nm UV laser

- remove metal surface coating

-

-

中文简体

中文简体